Aluma Coat TW

Aluma Coat TW Specification

- Application Method

- By Brush / Spray

- Particle Size

- 60 - 65 microns

- Max Temperature(Degree Celcius)

- 150 0C

- Thickness

- About 0.8 - 1 mm Millimeter (mm)

- Material

- Epoxy

- Form

- Liquid Coating

- Color

- Terracotta Brown, Grey, Blue & Green

- Purity(%)

- 99 %

- Application

- Industrial

About Aluma Coat TW

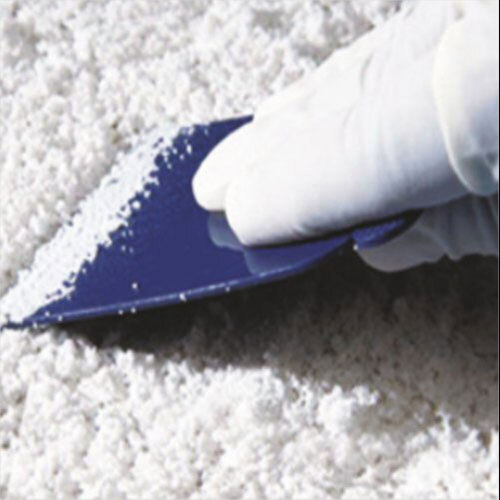

Aluma Coat - TW A corrosion, abrasion and chemical resistant coating. USP : Converts soft surfaces to abrasion and corrosion resistant. Aluma-coat TW : A 2 part epoxy resin based coating compound. It comprises of sintered sapphire hard aluminium oxide ceramic micro beads doped in resin, designed to resist chemical attack, cavitations, abrasion, moderate impact and also withstand maximum temperature upto1500C / 3200F.Aluma-coat TW can be applied on any surface such as ferrous, non-ferrous metals, stone, concrete, wood, plastics etc. Use in major industries : Mining and mineral processing, Cement, Power, Petrochemical, Paper and paper pulp, Fertilizers, Dredging and a host of surface treatments requiring corrosion and abrasion resistance. Areas of applications : Chutes, Rod and ball mill feed plates, Pan feeders, Conveyors, Bucket elevators, Dust collectors, Cyclones, Soil and rock box outlets, Hoppers, Classifiers, Pipe elbows, Slurry lines, Coat exhausters, Chip cyclones, Tanks, Dredging equipments etc. Aluma coat is a protective coating providing surface resistant to sliding abrasion, corrosion and chemical attack except hydrofluoric acid and temperature resistant upto150C (302F)ALUMA COAT IS AN EXCELLENT TO ANY PLANTS PREVENTIVE MAINTENANCE PROGRAM WHERE ABRASION & CORROSION ARE CHRONIC PROBLEMShelf Life of Aluma Coat TW Resin part at25-30 C/77-86F: around 24 months in original air tight container.Shelf life of Aluma Coat TW Hardener at25-30 C/77-86F: around 24 months in original air tight container. Technical Parameters Aluma Coat TW (Trowelable) Mixing Ratio 100 : 4 By weight Thinning Agent (Acetone / Xylene) Not Recommend Dry film thickness (DFT) 5 mm to 6 mm Coverage Area 0.1 Sq.mtr/kg at about 5 MM thick Coat Temperature Resist 1500C (3020F) Drying /Curing 24 Hours Air Drying @ Ambient Temperature Note : Surface should be thoroughly cleaned & abraded before application of Aluma Coat TWTechnical Details.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email