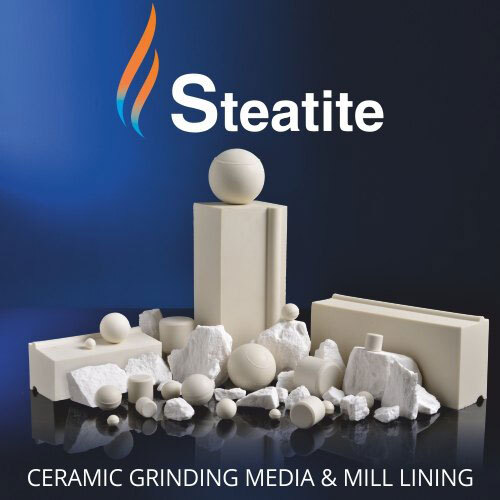

Steatite Mill Lining & Grinding Media

Steatite Mill Lining & Grinding Media Specification

- Surface Finish

- Smooth

- Density

- 2.70 0.05 Gram per cubic centimeter(g/cm3)

- Hardness (%)

- 520 - 550 Hv5

- Application

- Wet & Dry Milling

- Water Absorption

- 0%

- Chemical Composition

- SiO2, 61.5%

- Shape

- Spherical balls & Cylinders

- Porosity

- Nil

- Color

- Off White

About Steatite Mill Lining & Grinding Media

Steatite is a magnesium meta silicate composite formulated from selected quality soapstone, china clay, barium carbonate and other chemicals in its residual. The raw mix composite is wet milled to micro fine particle size. The composite slurry is spray dried to form homogeneous free flowing spherical granules. Such granules are pressed at high pressure compaction in T.C. moulding tools in uniaxial automatic compacting presses.

The pressed mill lining blocks and grinding media are sintered in high temperature kilns to form an impervious, vitrified, tough, non porous, dense hard material. Due to its mechanical strength and other relative features steatite ceramic is found most suitable ceramic composite for ball mill linings and grinding media.

The true value of mill lining and grinding media is measured by length of trouble free service in relation to mill production output. Our steatite grinding media is well known for its excellent quality, optimum milling results and longer service life.

| Physical Properties | ||

| Colour | -- | Off White |

| Density | g/cm3 | 2.70 0.05 |

| Bulk Density | kg/ltr | 1.60 0.05 |

| Water absorption | % | 0.00 |

| | | |

| Flexural strength | Mpa | 130 |

| Compressive strength | Mpa | 850 |

| Vickers hardness | Hv5 (kg/mm2) | 520 - 550 |

| Hardness on Mohs scale | -- | 7 |

| Co-efficient of linear thermal expansion (20 1000 ) | X 10-6 / | 8.5 |

| Safe operating temperature (No load) |

| 1050 |

| Volume resistivity (20 ) | - cm | 1013 |

| Cumulative Wear loss / hr after 120 hrs of wear test | % | 0.025 |

| Chemical Properties |

| |

| SiO2 | 61.5% | |

| MgO | 27.4% | |

| BaO | 3.2% | |

| Al2O3 | 6.8% | |

| Fe2O3 | 0.5% | |

| Na2O | 0.1% | |

| CaO | 0.5% | |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+