Zirconox Micro - Macro Media

Zirconox Micro - Macro Media Specification

- Chemical Composition

- ZrO2 83%

- Application

- Milling, Shot Peening & Polishing

- Density

- 6.20 0.05 Gram per cubic centimeter(g/cm3)

- Surface Finish

- Glossy, Satin Smooth

- Hardness (%)

- 9

- Water Absorption

- Nil

- Shape

- Other

- Porosity

- Nil

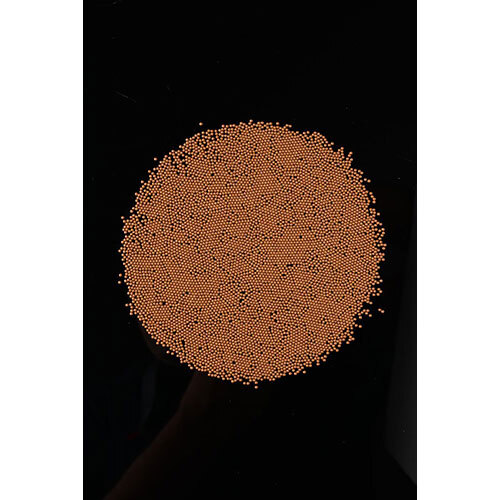

- Color

- Golden brown

Zirconox Micro - Macro Media Trade Information

- Minimum Order Quantity

- 100 Units

- Supply Ability

- 500 Units Per Day

- Delivery Time

- 7 Days

About Zirconox Micro - Macro Media

Zirconox- The wonder Ceramic Micro-Macro Milling media. Jyoti Ceramic is the proud manufacturer of Zirconox milling media, exporting 70% of its production to 55 countries for over three decades. Zirconox milling media has proved to be the most efficient, cost effective milling media in varied industries. Zirconox was formulated in 1990s from micro fine monoclinic zirconia powder stabilized with rare earth Cerium Oxide sintered to tetragonal polycrystals.Zirconox micro beads have a density of 6.20g/cm3and bulk density of 3.85 kg/ltr. With combination of high density & hardness, desired particle size of pigment or slurry will be achieved faster, resulting in reduced milling time and highest milling efficiency. Fraunhofer Institute, Freising, Germany has approved Zirconox micro media for milling of food stuff in accordance with the regulations of the European Community.Applications : Zirconox micro beads are being used in varied industries for micro fine milling & dispersion of : Agro chemicals: Fungicides, Herbicides pesticides.Adhesive, Sealants & Glues. Ceramic: Ceramic Inks, Engobes, Glazes, Frits, Enamels, Pigments. Cosmetics. Dyestuff: Textile dyes, Textile Inks. Electronic materials: Lithium Iron Phosphate battery. Food Stuff. Inks: Printing inks, Inkjet - Magnetic inks, Tattoo inks. Minerals: Calcium Carbonate.Metal: Gold, Silver, Platinum. Oxides: Titanium Dioxide, Zirconium Oxide. Paints & Varnishes: Auto & allied paints, Decorative & Marine paints. Pharmaceuticals.Zirconox beads are also used for shot peening treatment on metal surfaces, metal polishing, contact eye lenses polishing and a host of many other applications. Advantages of Zirconox microbeads Zirconox microbeads have a density of 6.20g/cm3and a bulk density of 3.85 kg/ltr hardness 9 on Mohs scale. The combination of high density and hardness of Zirconox microbeads allows for faster achievement of the required particle size of pigment or slurry, resulting in higher material yield with reduced milling time. Zirconox microbeads are the most cost-effective for speedy dispersion and micro-fine milling of high viscous (15000-50000 cPs) hard and soft substances with insignificant contamination from media wear. Zirconox beads are free from pinholes, cracks, bead fused with other bead resulting in reduced downtime and greater process safety. Zirconox microbeads have a dense, homogeneous internal microstructure. Due to microfine grain size beads have a satin-smooth surface finish and do not crack or shatter easily. The wear rate of Zirconox micro beads decreases as the milling hours progress and the surface finish of the beads appears glossier. Zirconox microbeads are extremely gentle to expensive mill parts. The wear of mill parts is extremely low with the use of Zirconox beads. Zirconox 90% beads maintain sphericity 80.95. Due to greater sphericity and satin-smooth surface, media flow improves and decreases abrasion. Zirconox beads last 300-350 times longer than glass beads, 25-30 times longer than MgO stabilized beads, and 20-30 times longer than Zirconium Silicate beads. Physical Propertise Colour Golden brown Surface Finish Glossy, Satin Smooth Density 6.200.05g/cm3 Bulk Density 3.850.15 kg/ltr Porosity Nil Water absorption Nil Hardness on Mohs scale 9 Hardness on Vickers scale (Hv5) 1250-1300 Crushing strength (dia 1.5mm bead) 215 kgf Bead Sphericity 90% 0.95 % Cumulative weight loss / HR(wear test conducted with water) After 24 hrs. 0.0015 After 96 hrs 0.0010 Chemical Properties ZrO2 83% CeO2 17%.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email